Pulsed ultraviolet light can be an efficient different to some of the antimicrobial technologies now applied by the poultry field to kill pathogens on eggshells, in accordance to Penn Condition scientists, who simulated creation situations to test the technological know-how.

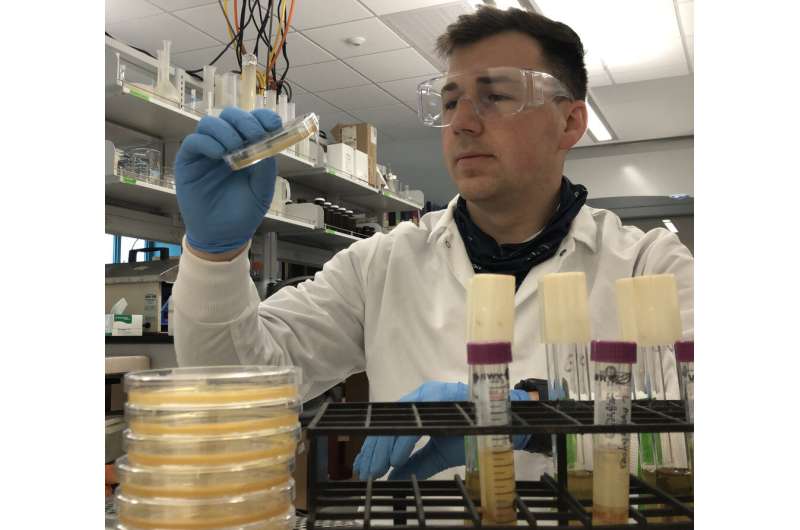

Researcher Paul Patterson, professor of poultry science, School of Agricultural Sciences, implies the technology has benefit for business application in the egg field.

“This examine is unique due to the fact it scaled-up and utilized components of conventional egg processing to a conveyor and sanitizing eggs in a industrial placing,” he mentioned. “In the absence of drinking water or other chemical sanitizers, this engineering has the prospective to obtain significant—equal or greater—microbial reductions than some at the moment obtainable technologies.”

Each and every calendar year in the United States, an common of 287 eggs are consumed for every particular person, and a lot more than 14.1 billion eggs are set in hatchery incubators to produce chicks destined for the egg and meat hen industries. By decreasing the microbial load on eggs, foodborne ailment outbreaks related with eggs and poultry meat can be diminished when chick wellbeing is maintained.

The egg market at the moment works by using sanitizers and detergents to decontaminate eggs and wash off any bodily particles, though low-depth ultraviolet light-weight has been used as an further antimicrobial phase. Even so, pulsed ultraviolet mild is a lot more efficient, discussed direct researcher Josh Casser, doctoral prospect in animal science, due to the fact it provides a increased depth of ultraviolet light to the floor of the eggshell. That success in a better microbial reduction in a shorter period of time of time than typical ultraviolet gentle therapy.

In this examine, the surfaces of shell eggs had been inoculated with nonpathogenic bacteria strains utilized for investigation and were addressed with pulsed ultraviolet gentle derived from a xenon flashlamp. Eggs were being exposed on a modified egg-carrying conveyor that furnished total rotation of eggs underneath the flashlamp.

The novel conveyor devised for the experiment was instrumental in reaching satisfactory decontamination, Casser noted, adding that the xenon flashlamps could be scaled up and tailored for any business set up.

“As the egg rotates on its very long axis along the way, the entire floor of the eggshell is exposed to the pulsed ultraviolet light-weight energy, and the 27 seconds of publicity in our experiment resulted in an suitable germicidal reaction,” he said. “At three pulses for every next, just about every egg is exposed to nearly 90 pulses, and every single pulse has a length of 360 microseconds—an really short duration pulse.”

The researchers, who not too long ago posted their outcomes in Poultry Science, discovered that pulsed ultraviolet gentle cure inactivated two distinctive microbial strains, with greater power resulting in a higher germicidal response.

The research also evaluated the consequences of pulsed ultraviolet light-weight treatment of hatching eggs on both embryo and chick expansion. Applying the exact procedure, 4 batches of 125 fertile eggs were being dealt with with the very same and increased intensities of pulsed ultraviolet mild. Following processing, eggs ended up placed in a industrial incubator under standard incubation ailments.

There was no sizeable outcome of the pulsed ultraviolet light-weight procedure on p.c fertility, hatchability or hatch. Also, there were being no considerable effects on post-hatch observations, which include chick livability and ordinary chook excess weight at hatch or at 42 times of age.

“Our exploration supports the application of pulsed ultraviolet mild as an effective antimicrobial intervention for equally desk and hatching eggs,” Cassar claimed. “If the egg business embraces pulsed ultraviolet light technology and applies it in its processing functions, meals security would be enhanced since of the minimized pathogen existence on the area of the eggs. And that matters since 9% of all foodborne sickness in the U.S. is related with eggs.”

The engineering is in particular promising since it seems to have no detrimental implications for the essential hatching-eggs part of the enterprise, even at 10 moments the UV-mild intensity utilized in the desk egg study, Patterson pointed out. Hatcheries make the replacement inventory for both the egg and broiler flocks of the poultry industry, which include turkeys.

“Our study confirmed that there are no adverse results on hatching eggs and the embryos and chicks that are derived from these addressed eggs,” he explained. “Working with pulsed ultraviolet light right before incubation in a hatchery environment would increase chick health and fitness, would prevent some of the monetary constraints induced by lousy chick high-quality ensuing from chicks acquiring sick from early publicity to microbial pathogens, and perhaps would make improvements to the food items security of poultry meat.”

Researchers discover how a bio-pesticide functions against spider mites

J.R. Cassar et al, The efficacy of pulsed ultraviolet mild processing for desk and hatching eggs, Poultry Science (2020). DOI: 10.1016/j.psj.2020.12.021

Citation:

Pulsed ultraviolet gentle technologies to increase egg safety, help poultry industry (2021, January 14)

retrieved 16 January 2021

from https://phys.org/information/2021-01-pulsed-ultraviolet-technological know-how-egg-protection.html

This document is issue to copyright. Aside from any truthful dealing for the function of private study or study, no

section may be reproduced devoid of the written authorization. The content material is presented for information applications only.

More Stories

Why Information Technology is Key to Growth

Information Technology: Your Pathway to Innovation

Unlocking the Future of Information Technology